- HOME

- ABOUT GOOGOL

- PRODUCTS

DIESEL ENGINE

GENERATOR SETS

- DOWNLOAD

- CASES

- NEWS

- CONTACT US

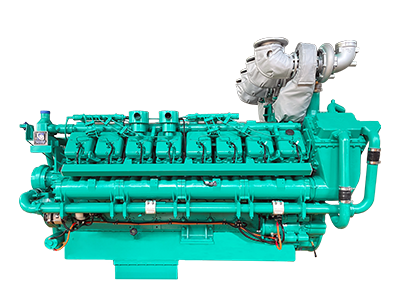

DIESEL ENGINE

GENERATOR SETS

The cooling system of a diesel engine is like a precise "temperature manager", ensuring that the engine can maintain normal operating temperature under different working conditions through a series of cleverly designed and coordinated components.

The core component of the cooling system is the radiator, which is like an efficient heat exchanger. The high-temperature coolant generated by the engine operation flows out of the engine and enters the radiator under the drive of the water pump. The radiator has numerous fine pipes and fins, which increase the contact area with the outside air. When the vehicle is in motion, the external cold air quickly flows through the radiator, taking away the heat in the coolant, causing the coolant temperature to decrease. Then, the low-temperature coolant flows back to the engine, and this cycle continues to cool the engine.

The thermostat plays the role of an "intelligent valve" in this process. During the cold start phase of the engine, the thermostat is closed and the coolant only circulates slightly inside the engine. This allows the engine to quickly warm up to the appropriate operating temperature, reducing engine wear and fuel consumption. When the engine temperature reaches a certain level, the thermostat opens and the coolant enters the large circulation, flowing through the radiator for sufficient heat dissipation, thereby accurately regulating the engine temperature.

Cooling fans are also an indispensable part. When the vehicle is driving at low speed or idling, the external air flow rate is insufficient to meet the heat dissipation needs of the radiator. At this time, the cooling fan starts to force air to flow through the radiator, enhancing the heat dissipation effect. The operating speed of the fan is usually intelligently adjusted by the engine control unit based on various factors such as coolant temperature and engine load, to ensure that the appropriate amount of heat dissipation air can be provided under various working conditions.

In addition to these main components, the characteristics of the coolant itself are also crucial. Coolant is generally a mixture of water and antifreeze, with a high specific heat capacity that can absorb a large amount of heat while its own temperature rises relatively slowly. At the same time, antifreeze can also lower the freezing point of the coolant, preventing the coolant from freezing, expanding, and damaging the engine in low-temperature environments.

On some large diesel engines or engines with special operating conditions, auxiliary cooling devices such as oil coolers and intercoolers are also equipped. The oil cooler is used to lower the temperature of the oil and ensure good lubrication performance of the oil; The intercooler is used in turbocharged engines to cool the compressed high-temperature air, increase air density, and improve the intake efficiency and combustion effect of the engine.

In short, the cooling system of diesel engines forms an efficient and intelligent temperature control system through the coordinated operation of radiators, thermostats, cooling fans, coolant, and a series of auxiliary devices. No matter what operating conditions the engine is in, it can stabilize its temperature within a suitable range, ensuring reliable operation and excellent performance of the engine.